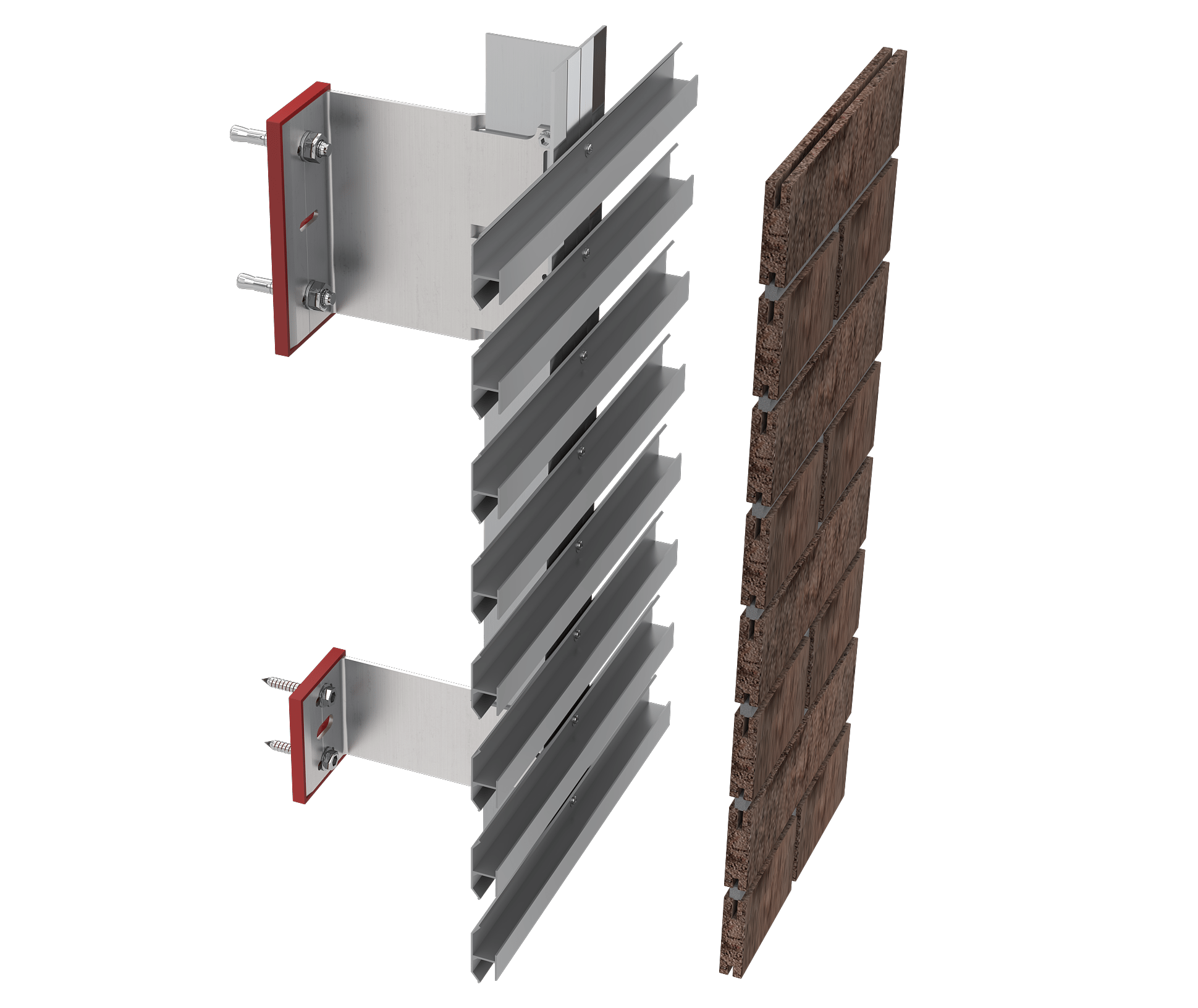

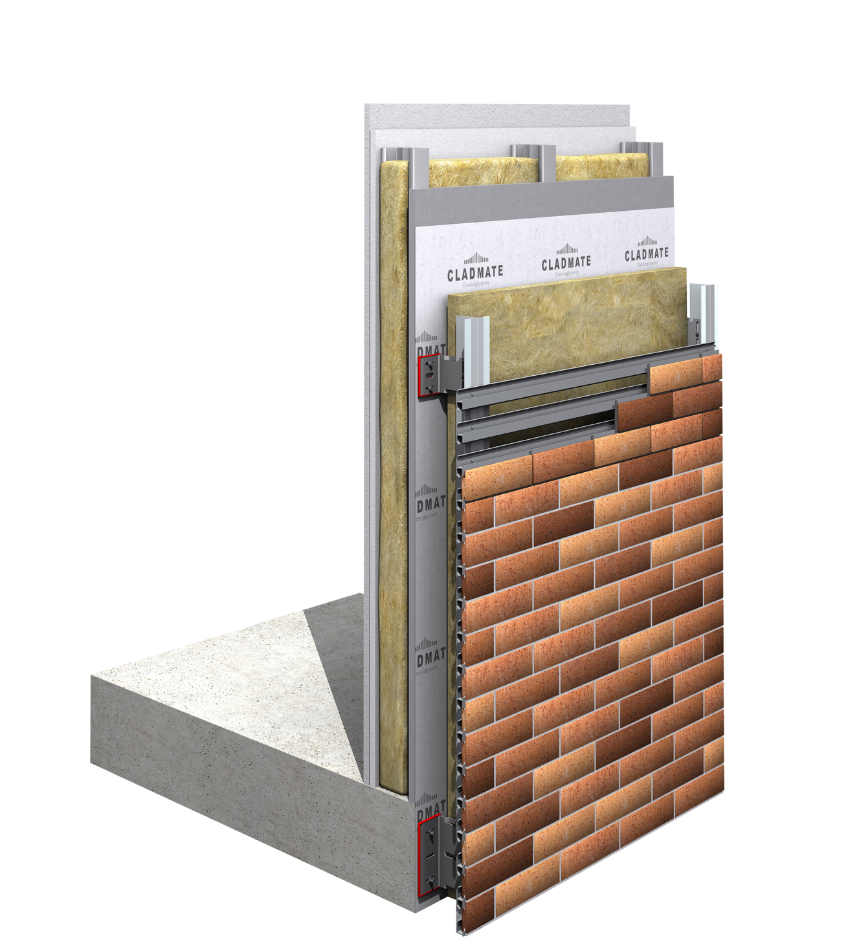

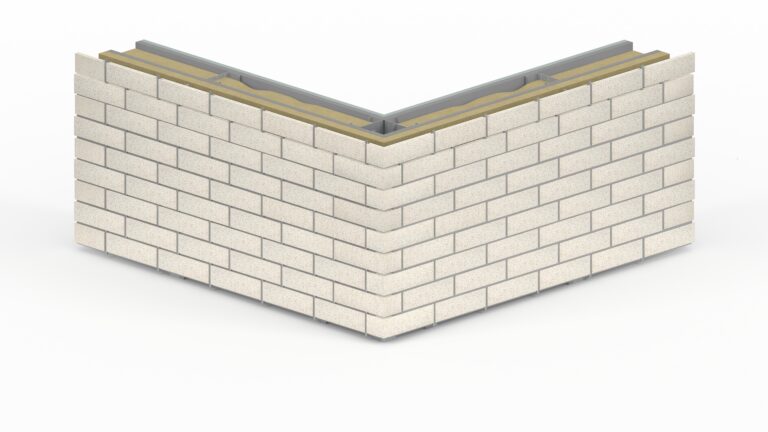

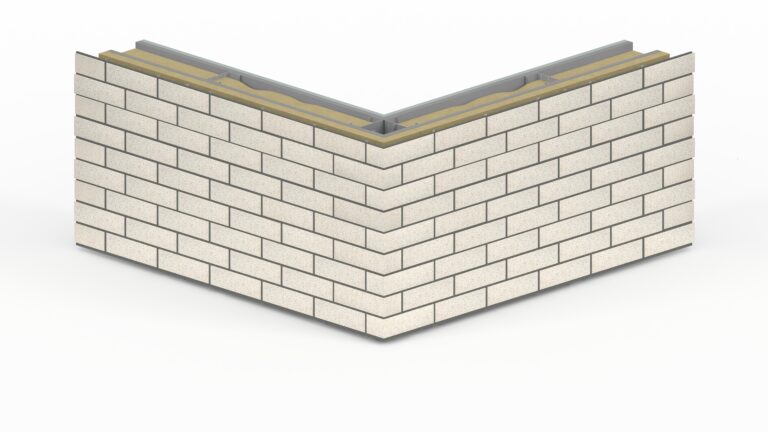

The CMS40 MF Slip Brick Slip Support System is a mechanically fixed brick slips cladding which stands out with its easy installation and minimal maintenance. The system provides a lightweight yet durable solution to traditional brickwork without compromising the aesthetics. Engineered as completely fireproof, it aims to save users time and money with low installation and maintenance costs.

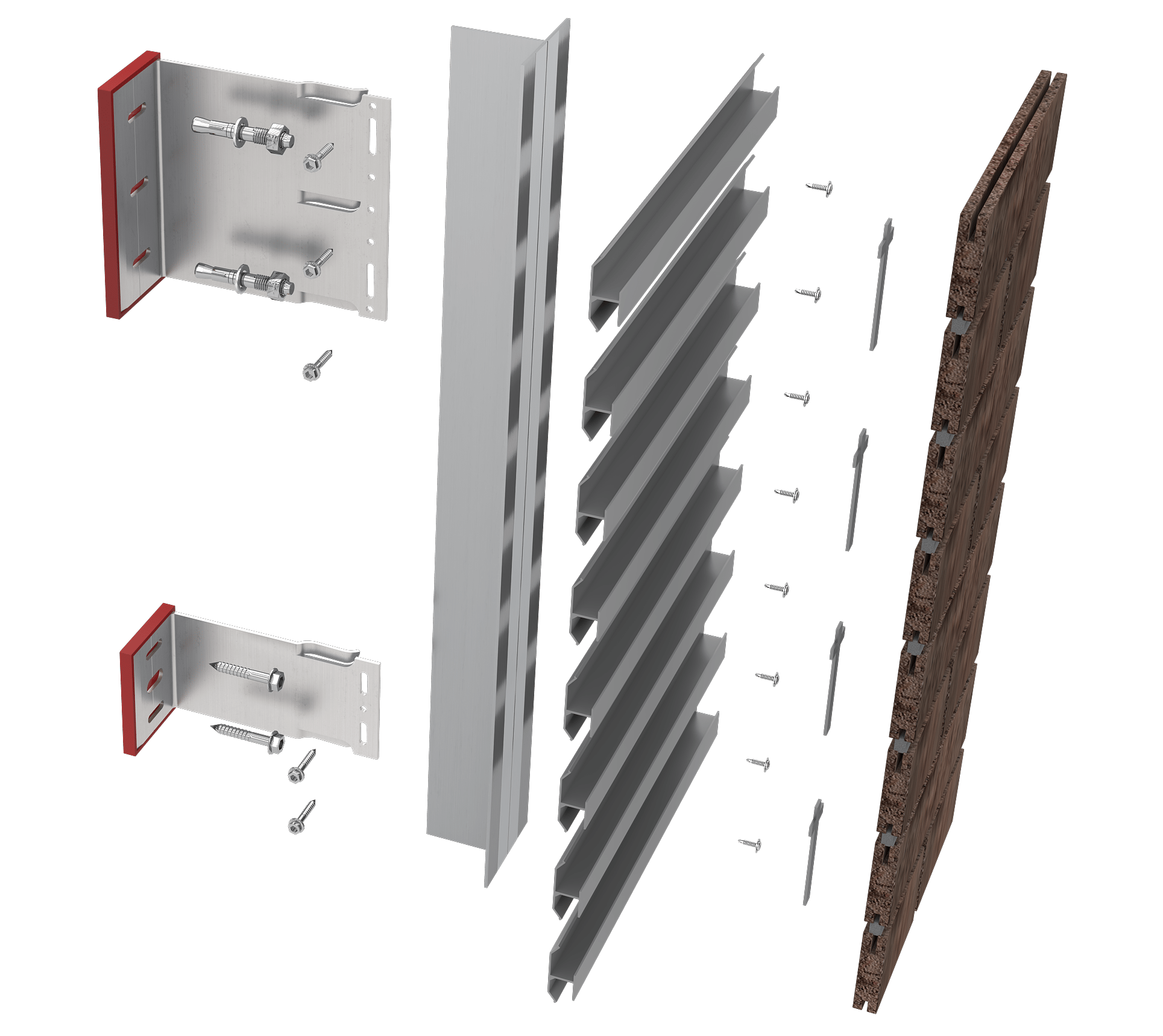

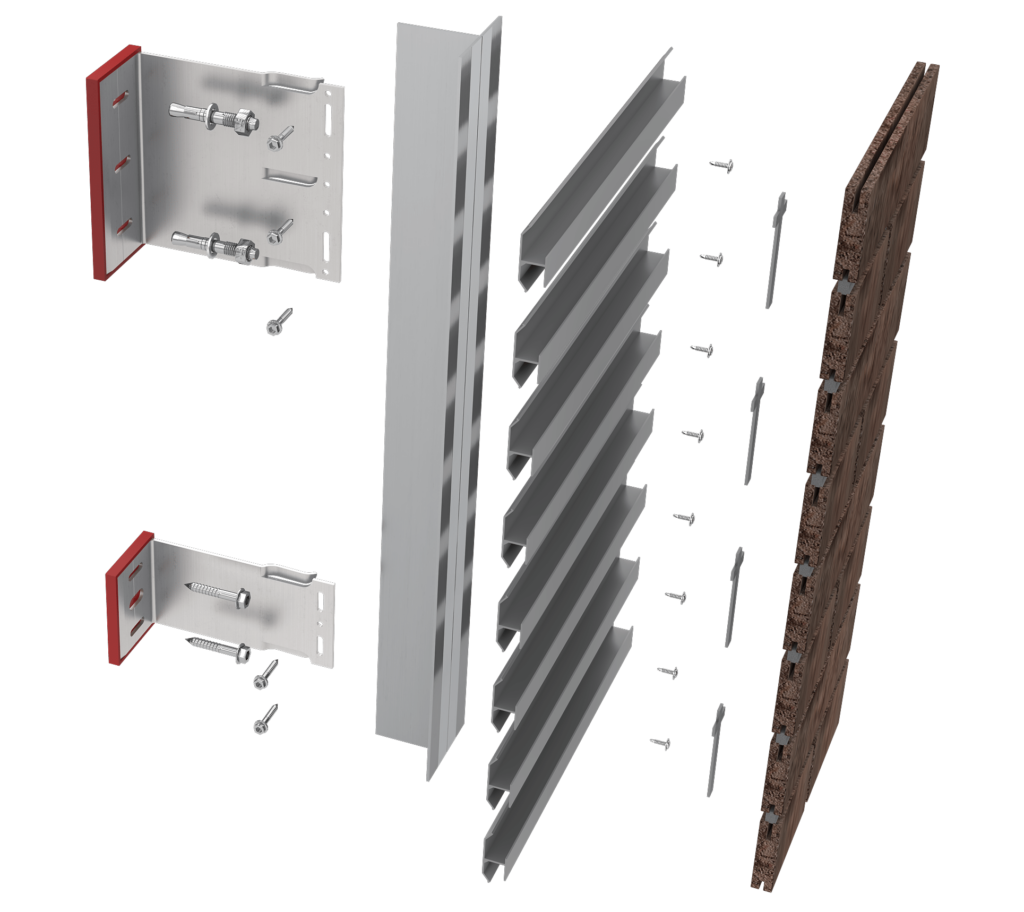

Double Helping Hand Brackets

Single Helping Hand Brackets

Fixing

EJOT fixings for timber/steel

studwork, masonry, concrete,

brickwork and

blockwork substrates.

Profiles

Horizontal Support Rail (Top, Mid & Bottom)

Brick Slips

22mm Clay Brick Slip, extruded/cut

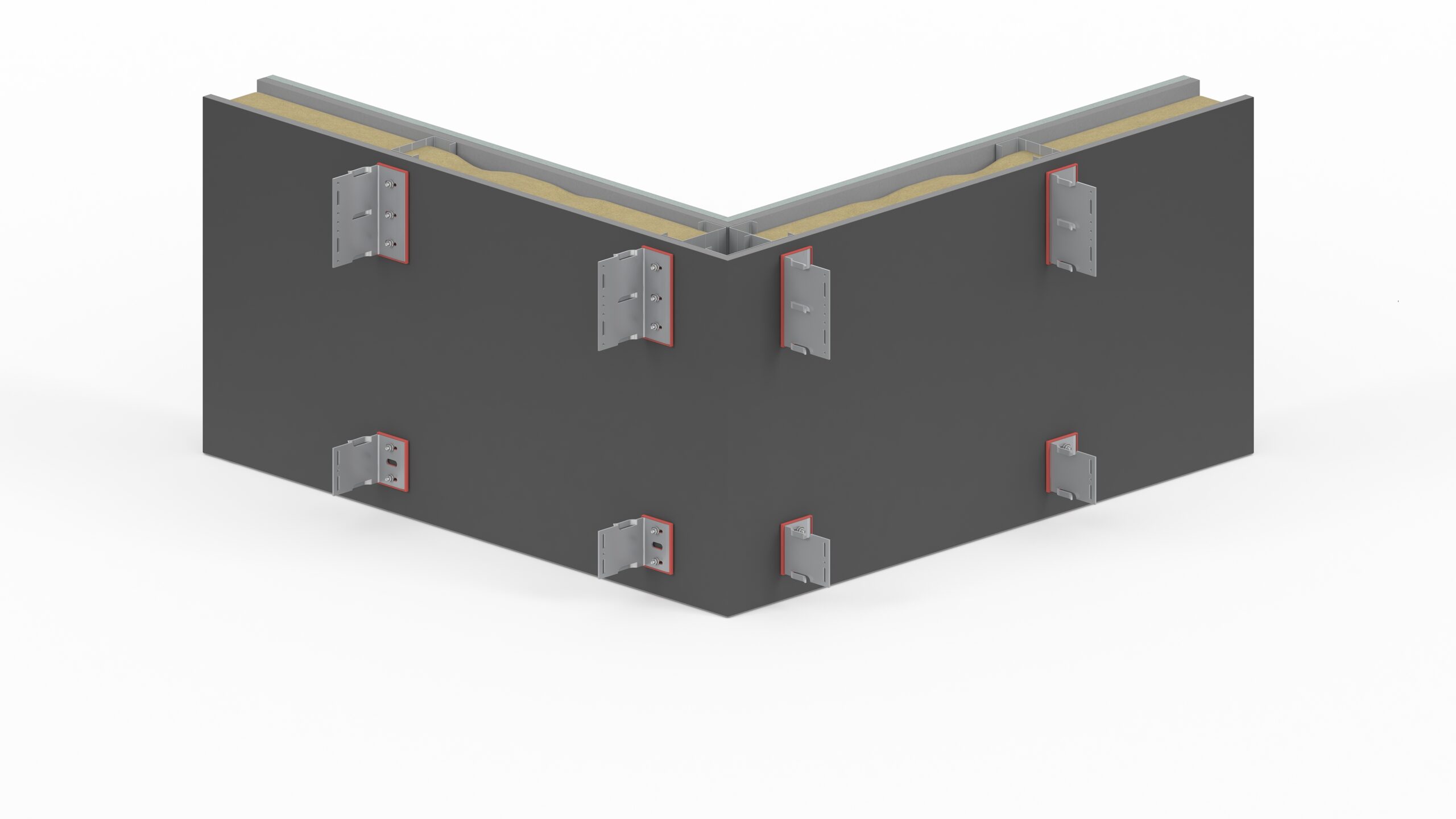

Fix Helping Hand Brackets to the substrate. Keep a maximum spacing of 600mm horizontally and 1200mm.

Place stone wool insulation in a staggered arrangement, securing it with a central washer and perimeter fixings positioned between adjoining slabs.

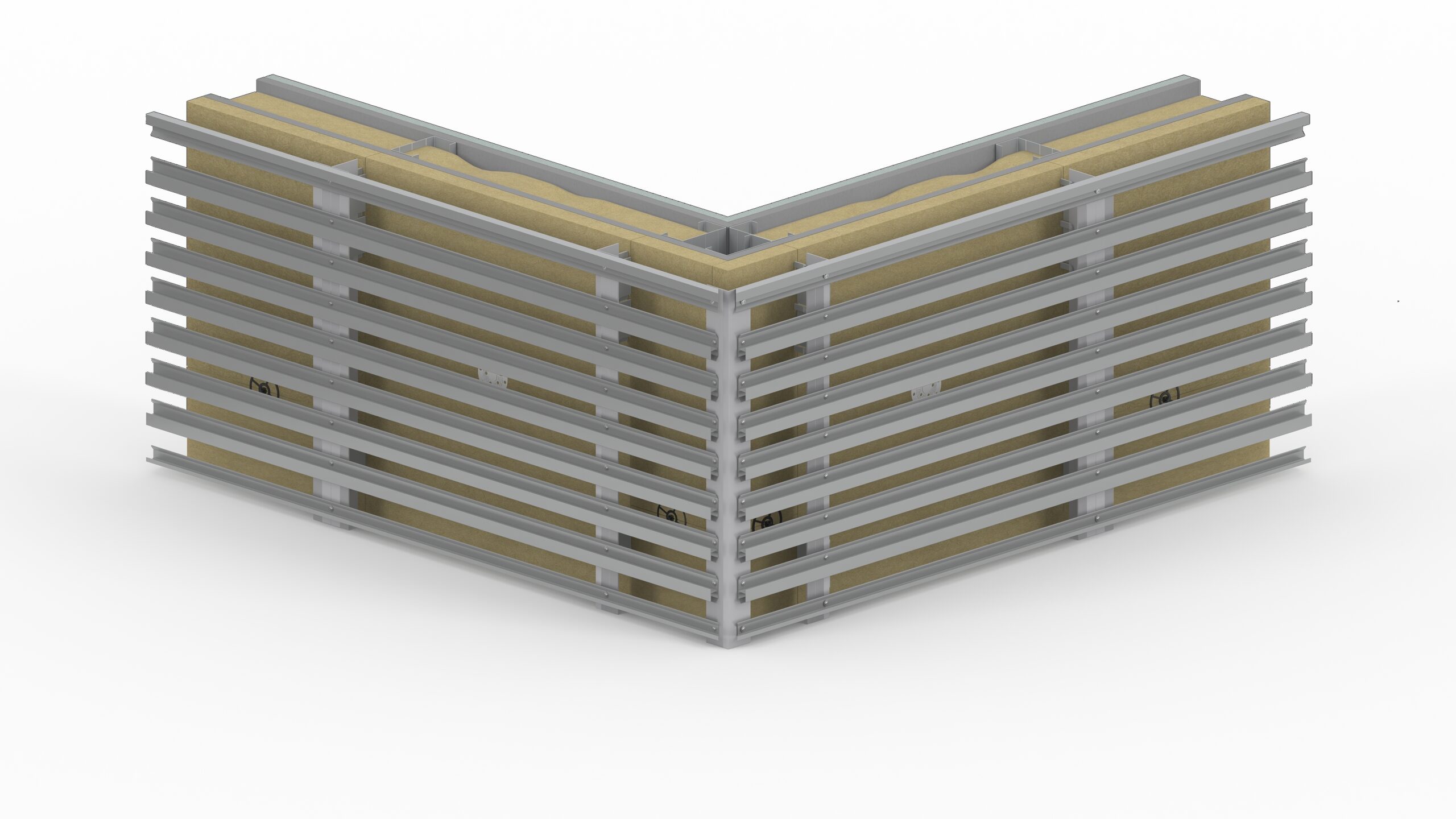

Attach T/L rails to the Helping Hand Brackets. Employ one bracket as a fixed anchor point and brackets with slotted points for the remaining connections.

Secure Horizontal Support Rails to the T/L rails. Align them precisely with the brick slips, creating a 10mm gap. Utilize the gauge tool for streamlined attachment of multiple rail courses.

Position brick slips meticulously between rails, following the upper and lower grooves for guidance. Preserve a consistent 10mm gap by employing metal brick spacers.

Upon completing the placement of brick slips, inject the joints with Parex Historic mortar to achieve an authentic clay brick appearance.